- SBCA Relaunches the Lumber Connection podcast! Each week experts in the lumber industry will provide insight on the most common lumber species and grades to help component manufacturers make lumber buying decisions.

- Forklift Solution Parts was founded in New Jersey but ships all forklift parts nationwide. Forklift Solution Parts is a friendly, family owned forklift parts store that also has new and used parts. Our goal is to provide you with the very best and affordable parts for your forklifts.

Toyota Forklift History

When business owners want to go to experts in construction and materials transport, Toyota is a brand they always put in their list. That’s not a surprising decision since the Toyota forklifts available in the market have made themselves a name already over the years to be reliable, powerful and cost-effective. Toyota Forklifts are considered the world’s leading provider of pallet jacks, scissor lifts, forklifts, scissor lifts and reach trucks, and over the years all of these engines’ reliability are still second to none.

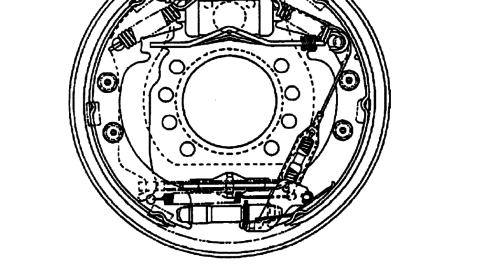

Some of the major forklift parts include forklift engine parts like flywheel assemblies, belts, alternators, etc., forklift filters like hydraulic filters, air filters, transmission filters, etc., forklift brake parts like brake shoes, wheel cylinders, brake lines, etc.

Toyota Material Handling Group and Toyota Group's History

Although Toyota Material Handling Group is a relatively new company, the name 'Toyota Group' has been around for over a century. The steps along the way for over a century of Toyota Group tell the tale of a demanding journey and determination. In 1867, Toyota Group was formally established by Sakichi Toyoda. For the first few decades, the company was involved in the production of passenger cars. In 1956, it officially joined the material handling industry by manufacturing its first forklift model, LA 1-ton forklift truck, followed by the model LAT 0.85-ton towing tractor the next year.Within a decade, Toyota was all set to launch its first electric counter balanced forklift truck, which was formally introduced in 1967. To meet the increasing demands, Toyota built the Takahama plant, which was constructed primarily for the production of industrial equipment, including forklift trucks. The new facility was officially opened in 1970 and at the same time, they introduced the Model FBR10/15 1-ton electric reach truck. Another first for the company was the introduction of the FBE model, Narrow Ace. It is a three wheeled electric counterbalanced forklift truck, which was the first among domestic manufactures of forklifts and was introduced in 1978. In 1985, Toyota achieved a milestone by producing the 500,000th forklift unit. Toyota acquired its international quality management certification, ISO9001, in 1994, which endorses the company's commitment to continually provide quality products to its customers. During the same year, Toyota crossed the benchmark of producing over 1 million forklift units. The international certification for being an environmentally friendly organization did not wait more than 4 years, and Toyota was an ISO14001 certified company by the year 1998.

Toyota Material Handling Group (TMHG) was formally established in 2006. It is in charge of production of Toyota forklift trucks, including the advanced materials handling solutions. This was also the time when the concept model of the hybrid forklift of Toyota was exhibited in Logis-Tech Japan. Year 2009 was marked with fielding of Geneo-Hybrid diesel powered IC lift truck by Toyota Material handling Group in Japan. In the drive of global expansion of forklift productions, THMG established its industrial equipment company in Vietnam to produce forklift trucks and warehouse equipment in 2011.

Toyota Range of Forklift Products

Safety is an important thing for Toyota, and engineers make sure that this is incorporated in every Toyota forklift truck. The forklift trucks feature the System Active Stability or SAS that can help lessen accidents and injuries in the workplace. The introduction of this technology helped pushed Toyota become an industry leader. Right now, more than 150,000 lift trucks are equipped with the technology.

Toyota offers a large variety of IC Cushion tire lift trucks, Pneumatic tires lift trucks, electrically operated Rider lift trucks, Pallet and Reach trucks. The IC trucks are available in 8–series;large capacity trucks capable of handling 8000 to 15,500 lbs. Operable with gas and LPG, Toyota 8-series forklift trucks are made exceptionally stable and powerful to carry heavy loads under tough circumstances. Reduced emissions and economical fuel consumption are the features coupled with strength and durability. Comprehensive ergonomic features like an 11.8 diameter two spoke steering wheel provides ample leg space to the operator. Cowl mounted hydraulic levers afford better controls and easy entry and exit in the cabin. Low profile front cowl provides better visibility and prevents the operator from an unnecessary forward leaning.

The 8-series IC served with Cushion tires are capable of handling 3000 to 6500 lbs. The machine operates with CNG and LPG and is served with System of Active Stability (SAS), which monitors the operation to prevent a tip over at any stage. With regards to ergonomics, the 8-series cushion tire forklift is equipped with a 4-way adjustable suspension seat and dash mounted instrument display, in addition to all of the features of high capacity forklift. The cushion tire served 8-series high capacity forklift truck to the same lift capacity of the pneumatic tire 8-series truck i.e. 8000 to 15,500 lbs. Ergonomics have been further improved to add comfort to the operator's day at work.

Toyota also invested in electric lift trucks. The 7-series electric forklift trucks have a wide range of products to offer the customers. They include 3 and 4-wheel cushion and Pneumatic, 4-wheel large capacity with cushion tires and AC pneumatic models. The company has also introduced the 8-series 4-wheel cushion tires model to its fleet.

The range of Toyota Reach trucks include single and double 8-series AC powered trucks, capable of handling 3000 to 4500 lbs lift capacity for the cube utilization. Ergonomically equipped Toyota Single and Double reach trucks are served with Bubble mat padding to manage vibrations and prevent accidental injury to feet and ankles. Driving seat is made much more comfortable with cushioned arm and backrest, whereas polyurethane drive tires help a smooth drive on rough surfaces.

Parts Of A Lift Truck

Toyota Forklifts Known for Industry-Leading Safety

Safety is an important factor for Toyota. Their engineers ensure that safety is integrated in every Toyota forklift truck. The forklift trucks feature the System Active Stability or SAS that help decrease accidents and injuries in the workplace. The introduction of this technology played a critical role in Toyota becoming an industry leader. Today, more than 150,000 lift trucks are equipped with the technology.

In an effort to promote safety in the workplace, Toyota now offers Operator Safety Training. The training helps business owners and customers meet or even exceed OSHA standards 1910.178.

Toyota Forklift Parts

The quality control system of Toyota makes sure that every single component is designed and manufactured to the highest standards of quality control and perfect tolerance levels similar to the forklift part it is going to replace. In order to make sure that customers gain maximum trade-in value and optimal performance, Toyota strives to manufacture parts of the best quality.

The lifetime of your forklifts will be augmented by the usage of genuine Toyota forklift spare parts that are manufactured to the best specifications and standards, guaranteeing the highest possible level of safety. Some of the major forklift parts include forklift engine parts like flywheel assemblies, belts, alternators, etc., forklift filters like hydraulic filters, air filters, transmission filters, etc., forklift brake parts like brake shoes, wheel cylinders, brake lines, etc.,

Toyota makes sure that customers gain immediate access to all the forklift parts they need, and also provides them with parts that are of high reliability, incurring lower cost of ownership and contain maximum service life.

Whatever forklift part you require, whether it is radiators, solenoids, and brake shoes, or just bolts, studs and nuts, the company makes sure that you receive them within 24 hours of ordering, without regard to your current location. The company's local warehouses network and service technicians make it possible for the company to source parts faster. Toyota makes sure that its service vans and depots are replenished on a daily basis to guarantee best availability of parts to its customers at all times.

Proven Process

Perhaps one distinguishing attribute of Toyota today is that it doesn’t cut corners, especially in their design and construction process. And this process does not just talk. It is proven. For 15 years, Toyota has been ranked to be World’s Top Forklift, and over these years there have already been 500,000+ Toyota forklifts manufactured in the USA sold all over the world. This easily makes it understandable why Toyota is still No. 1 in Durability, Reliability, Quality and Overall Value. When a businessman partners with Toyota, it means a partnership of excellence, sustainability, and longevity. Sustained investment is what you get every time you choose to request a Toyota forklift quote.

Trustworthiness

Today it’s never been easier to look for the right forklift that answers a business problem, but what people respect about Toyota is that it just doesn’t offer a forklift. Toyota offers a specific and most precise industrial solution. And you can trust that this solution is responsive to a company’s needs.

Forklift Components Ireland Map

It’s worth repeating here that Toyota Material Handling has undergone years of evolution and revolutionary challenges that adapt to the fluctuations of the market today. This is even more pronounced when in 2019 Toyota had revealed at the ProMat 2019 some of the revolutionary, new and next level forklifts in the company’s evolution. Material handling solutions are something that Toyota is an expert of, but to think that they’re still growing and innovating and evolving, there’s more reason why people should trust Toyota even more.

Assorted Forklifts Built To Perform

From 3-wheel Electric Forklifts, Stand-up Rider Forklift, Reach Truck to Core IC Pneumatic Forklifts, Toyota understands the importance of performance. Fortunately, Toyota has proof to show. Over 230 Toyota dealer locations all throughout North America is another proof that Toyota commands respect. It is an authority in forklifts also because of its 3,300 certified service technicians across North America growing the brand to its finest and most optimal level.

An example of the forklifts that bring Toyota to its prime name is the Versatility VIP Core IC Cushion Forklift. With 3,000 - 6,5000 Lb. Lifting Capacity and ingrained with System of Active Stability (SAS), companies are not to blame when they become partial to Toyota to answer for their various business needs. It helps, too, that this forklift has a CNG Power Available, giving it a more trustworthy reputation in the field of warehouse management, distribution applications and retail storefronts in general. It is this kind of dedication to versatility and power that makes Toyota still a trustworthy brand today.